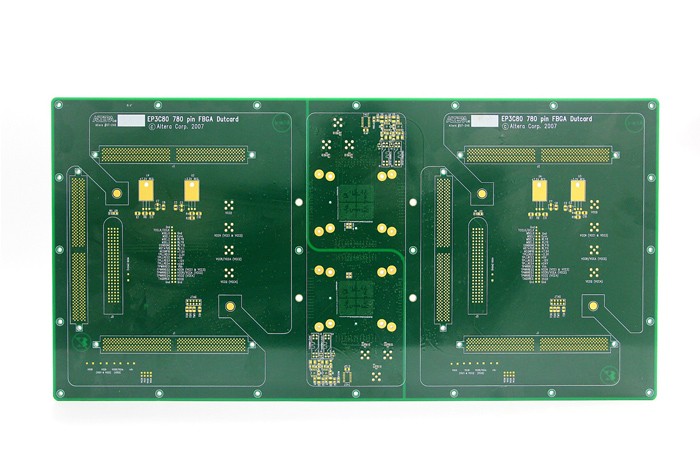

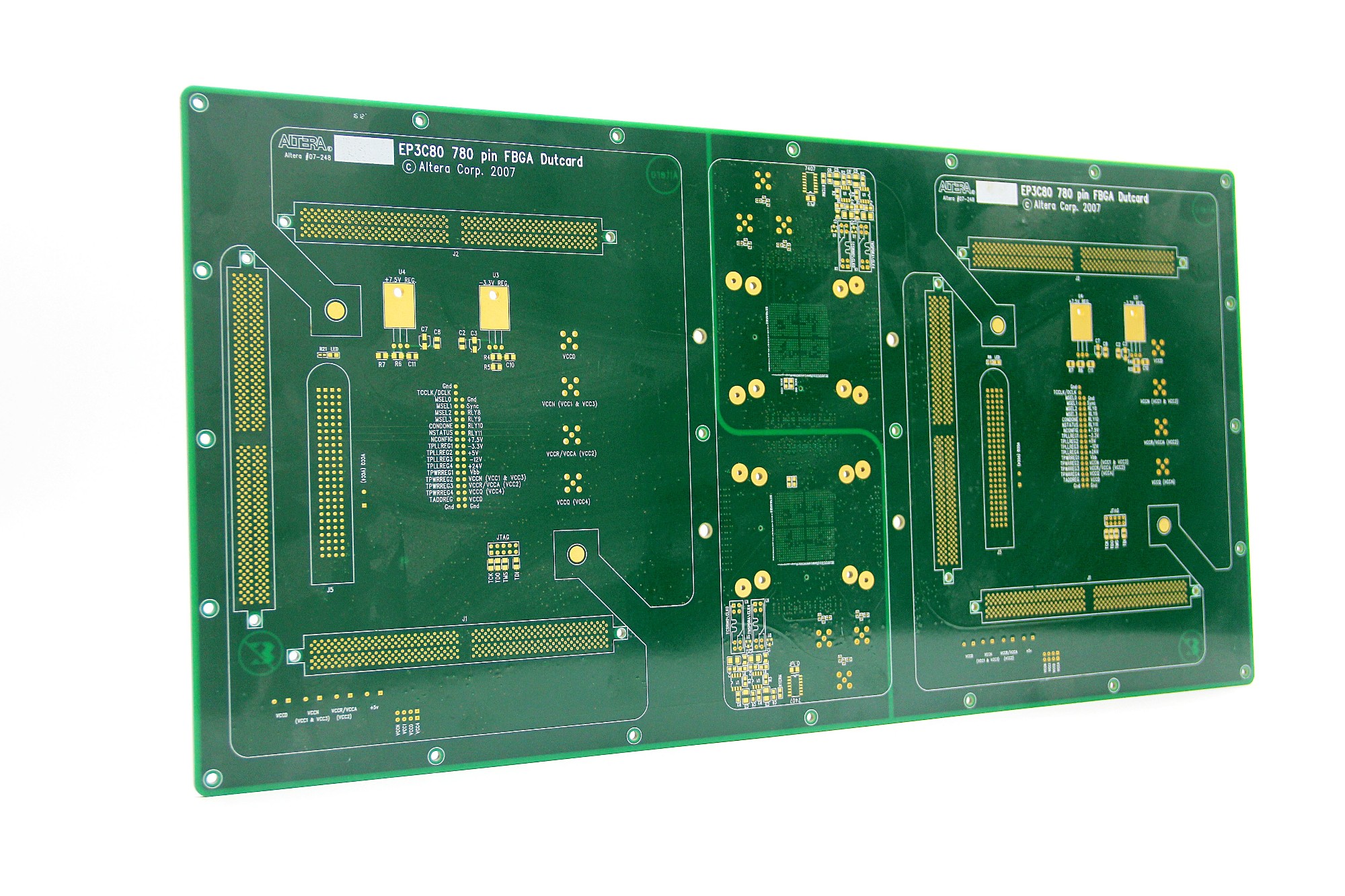

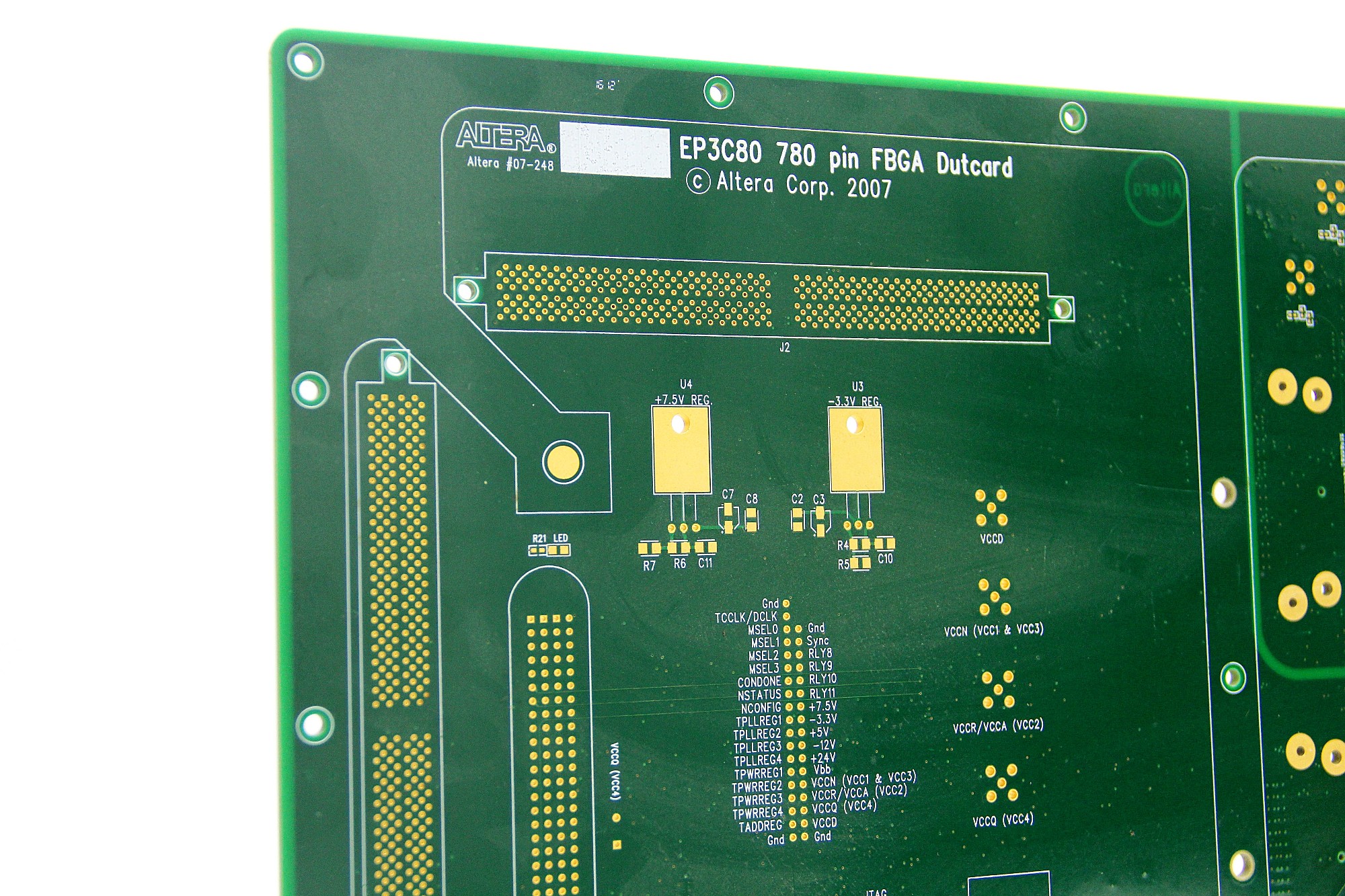

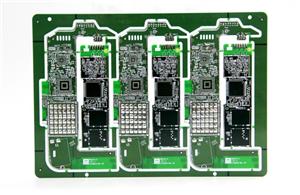

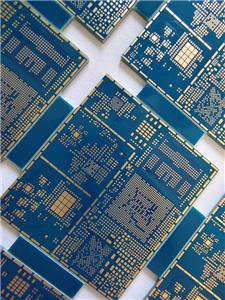

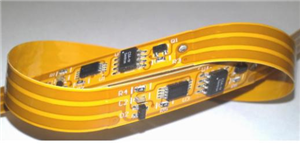

Immersion Tin Circuit Board

Brand :Multech

Product origin :China

Delivery time :7-9days

Supply capacity :88000sqm/month

Immersion Tin circuit board

1.6mm thickness

FR4 TG130

4/4mil line width/space

ENIG(1U”)

2oz finished

100% AOI Test

ISO.9001/CQC/ISO.TS16949/ROHS

Application:Consumer/home/network

A:Raw Material

Becu, Beryllium Copper,phosphor copper,Brass, Copper,Stainless steel,Aluminium ,SGCC,SECC,steel,spring steel,Nickel-Silver... and all different kinds of metal

B.SPEC

Roll material thickness is 0.05-10mm;sheet metal thickness is 0.3-20mm

C.Surface treatment

Gold / Silver /Tin / Nickel / Zinc / Chromium / Copper-plating / Laser etching/Screen printing/Phosphating (can pass salt spray testing with 160 hours)/Black coating / Painting/ Power coating /Electrophoresis / Passivating /Deburring / Polishing / Brush acording to ROHS standard

D.Application

All different kinds of telecom products,Automotive,high-end digital cameras,Medical Equipment, Remote,Washing machines , vacuum cleaners,desk lamp,Furniture, Switch Power Supply,Socket,water heater,High-end toys,Calculator,Electrical,Interphone, Wireless Mouse, Wifi Router,Cordless telephone,mobile phone,Mobile DVD,Sounder.Auto Clutch,bicycle brake,scooter and so on

E.Quotation

Please provide the Formal drawings (normally,with DWG/STP/PDF file ),and make note with material/QTY/surface treatment and any other requirments, we will provide you the quotation sheet in 48-72 hours

F.Prototype & Mould

We make the prototypes or moulds according to the drawings that confirmed by both of us and customers!The lead time is depends on the structure and qty of parts,Normally , lead time for prototypes is 3-15 days;leat time for mould is 10-25 days

G.Production

We will provide samples according to the drawings to customers for approval . then arrange the production and confirm the delivery date according to the Purchase Order;Normally , the lead time for production is 5-30 days ,the structure of parts is different , the lead time will be different .

H.Package

Plastic bags;Preserving Box;Reel/tape package;Plastic tray;Wood box;Export carton and any other customized package according to the customers' requests.

I.Machining equipment

CNC milling&turning machine, stamping machine ,milling machine, grinder machine ,drilling machine, and optical comparator etc

J.Test

tensile test,mist and salt test,hardness test

K.Process

bending, welding, casting, tapping, drawing, punching, flanging etc

-

Download

- Multech Capability of rigid-PCB.pdf